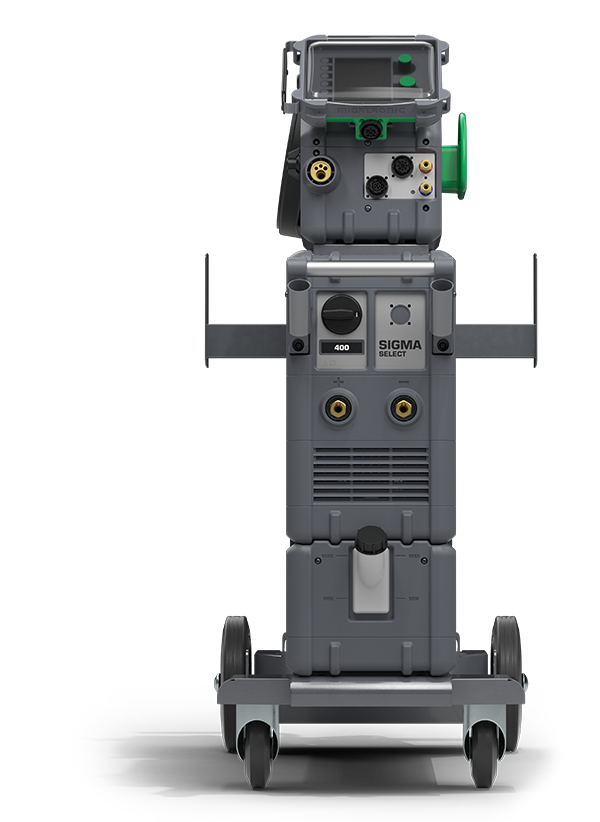

Sigma Select

Built to meet the future

Through years of experience and innovation, Sigma Select is designed for welding in a league of its own. It makes the most complex welding tasks seem easy, and it makes you capable of producing welds of the highest quality in every material – from mild steel to special alloys.

- Customise Sigma Select to fit your needs

- Upgrade the machine throughout its entire service life

- Select welding functions such as DUO Plus, IAC and MigaLog

- Advanced equipment, simple to operate

Sigma Select is ideal for devoted welders in professional welding productions. The perfect machine for site welding operations and heavy industry.

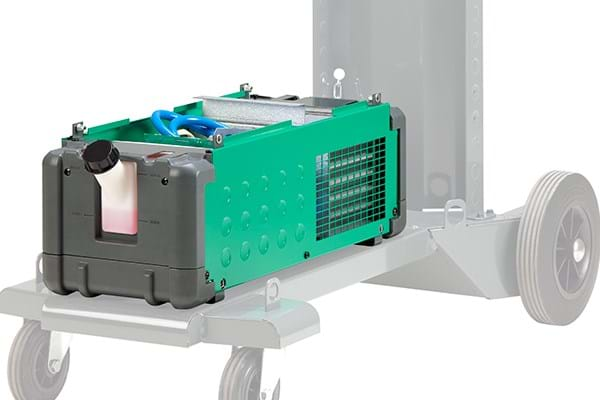

Adaptable solution for complex welding

You know what you expect from your welding machine. Raw power, water-cooling and wide field of application? A compact workhorse packed with intelligent welding functions? We have developed a framework for customising your machine exactly as you desire. It allows you to configure the body and mind of your very own Sigma Select. No matter how you build it, user-friendliness, intelligent functions and top-of-the-line welding performance are included. Explore the possibilities.

Upgrade according to your needs

You don’t have to select all functions to begin with. You can instantly adapt Sigma Select to meet your current needs. If your customers make new demands on your welding production, simply upgrade your welding set-up by SD card. Add new functions for less than the cost of a new welding machine.

Graphic control panel

Sigma Select simplifies advanced welding thanks to the wide selection of programs and intelligent welding technologies. You can detach the robust and ergonomic control panel and take it with you. This allows you to adjust your settings without moving away from the welding spot. The graphical display makes it intuitive to navigate functions and adjust welding parameters, with visual presentation of how your changes affect the weld.

The graphic control panel allows you to upgrade to all future functions and welding programs. Even the basic version of this control panel provides you with language variants, process and machine set-up, service menu and other smart features.

Overview

Sigma Select product news

Separate wire feeder

Built-in control panel for Sigma Select Compact

Two wire feeders

Benefits

Highlighted features

WPS Lock Card

Detachable control panel

It's keen to be green

Experience large scale reductions of your gas consumption with Sigma Select.

Intelligent Gas Control® technology prevents over-consumption of gas

and gives you savings up to 50%.

Request a Sigma Select demo

Get close to the Sigma Select. We demonstrate the features of the welding machine, and you get the opportunity to weld and test all functions. Send your request here.