Sigma Core

High Amps. High simplicity

A simple MIG/MAG welding machine, built for light and heavy steel construction industries. Robust, straightforward and with just the core welding functions.

- Uncomplicated and effortless

- Minimising the technology gap

- Great welding performance

Simple welding machine with the core functions you need to weld.

Sigma Core is a simple welding machine with the core functions you need to weld - also at high amps. It is ideal for welders who demand simplicity in advanced welding. Use it for welding steel structures, prefabrication and thick plates in mild steel.

Simple to the core.

Easy to use.

Uncomplicated.

Effortless.

Sigma Core is ideal for welders who need simplicity and high welding performance. It holds the most essential elements and no unnecessary software, features or gadgets. Any welder, no matter the level of experience, will have no trouble adjusting the Sigma Core and start welding right away.

Minimising the

technology gap.

Sigma Core minimises the gap between ealier generation welding machines and modern day welding technology. It does so by offering an improved arc, which again improves weld quality. It is a more energy efficient solution that consumes less power and gas for an optimised production.

Great performance.

Low cost.

Great welding performance and modern day welding technology ought to be accessible for all kinds of welding productions. Large and small. High-tech or not. It calls for a cost-effective solution. This is it.

Configurations.

Stay put or move around.

Sigma Core Compact

Stay put

A compact welding machine is great if you want it to stay in a welding booth or be right next to the working table at all times. The length of the torch determines how far away from the welding machine, the welder can go.

Wire feeding

Compact

|

Cooling

Air or water

|

Control panel

Graphic |

Current range

15-230/270/300/400/550 A |

Sigma Core Separate

Move around

A welding machine with a separate wire feeder is great if you need to be able to move around during welding. The length of the intermediary cable determines how far away from the welding machine, the welder can go.

Wire feeding

Separate

|

Cooling

Air or water

|

Control panel

Graphic |

Current range

15-300/400/550 A |

Sigma Core 230/270.

High quality at low cost.

With tacho-controlled 4-wheel wire feeding, housed in our latest cabinet design, the Sigma Core 230 and 270 are not only smaller and lighter than our step-regulated predecessors, they are also more powerful and energy-efficient. With low costs, these machines offer unmatched value to the market.

Simple control.

Intuitive to navigate.

The graphic control panel is intuitive to navigate and easy to use for both welders and supervisors. It will contribute to making your daily working procedures efficient.

Graphic control panel

Visually compelling

This graphical control panel is designed to be easy to understand for all users. Welders with limited experience with digital welding machine displays will quickly grasp this simple design.

It is easy to find and adjust the core welding settings: amps, voltage and wire feed speed. It presents the wellknown settings in a simple, yet visually compelling way.

Intelligent Gas Control.

Save gas.

IGC® Intelligent Gas Control technology prevents over-consumption of gas and gives you long term savings. With weld pools always perfectly protected, you increase the quality of each weld. Your investment will quickly pay for itself.

No over-consumption at ignition

IGC

Intelligent Gas Control® automatically optimises your gas flow to current needs during every moment of your entire weld.

A traditional valve causes a large waste of gas. Welding with Intelligent Gas Control® prevents over-consumption of gas at the moment of ignition.

Every welder's closest ally.

Upgrade your torch.

Smart Torch modules

Fine-tune settings at the torch

A Smart Torch module is placed on the torch handle, providing easy access to adjusting a variety of welding parameters. Using the graphic display, the welder can fine-tune settings perfectly, all the way down to one amp - without being right next to the welding machine.

MIG-A Twist

Adjust the torch to the perfect angle

MIG-A Twist® ensures ergonomically correct working postures when welding in varying positions. Turn the swan neck 45° in both directions step-by-step at intervals of 15° and be able to use the correct working posture in all welding angles.

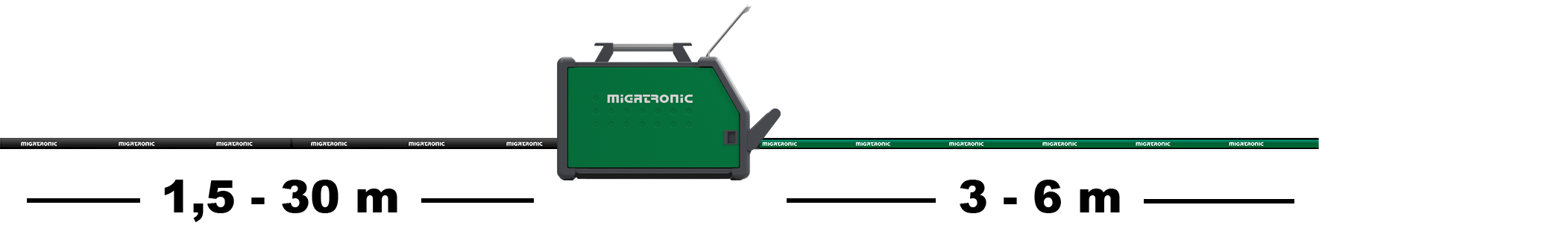

Welding cable lengths

Torches and intermediary cable lengths determine how far away from the welding machine the welder can go. There is a solution for your every need.

Sigma Core Compact

Configuration possibilities

Welding torch: 3 - 6 meters

Sigma Core Separate

Configuration possibilities

Welding torch: 3 - 6 meters

Interconnection cable: 1,5 - 30 meters

Service.

We got your back.

Our network of authorized service partners across Europe is ready to support your welding production.

Get serviced by our large service network

Authorized service partners have educated service technicians who are certified to perform professional service and maintenance.

They know your welding machine and their service vehicles are packed with original spare parts,

calibration measuring- and testing equipment.

Extend the warranty on your Sigma Core

You can be sure of high-quality products when you buy Migatronic. In addition to the warranty period of 2 years for new welding machines, you can extend the warranty up to 5 years.

To maintain the extended warranty, a yearly service check is required. Register your newly purchased Sigma Core on migatronic.com/warranty no later than 30 days from the date of purchase. Then you get up to 5 years warranty on selected components.