CoWelder improves working environment

Lower sickness absence

Lower sickness absence

Higher production efficiency

Higher production efficiency

Improved working conditions

Improved working conditions

Let's talk about how CoWelder can improve working conditions in your production.

Sure, let's talkAchieve higher efficiency, lower sickness absence and higher turnover

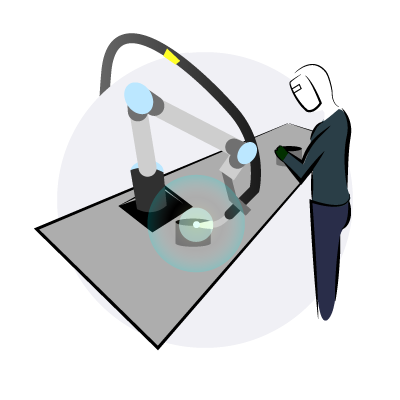

The CoWelder relieves the welders in your production and contributes to a better working environment. It carries out all the tiring, repetitive movements that cause muscle fatigue and physical strain. Moreover, welders avoid being exposed to direct radiation and welding fumes.

The CoWelder also helps increase your welders’ motivation and job satisfaction because the robot releases welders for more complex welding assignments. Ultimately, the robot contributes to improving productivity and results.

The CoWelder is not designed to replace manual labour. It optimises work processes in close collaboration with welders.

Relieved of exhausting work

"Welding can be hard work, especially when our welders are working on large batches. These assignments entail similar motions and static positions over long periods of time, which can be quite tough physically. With the CoWelder, our welders are relieved from this kind of work, which has remarkably improved their working environment."

Svein W. Kristiansen, general manager of Smed T. Kristiansen AS, Norway

Without CoWelder

Your dedicated welder may get back pains when welding in awkward positions in order to get the work done. Eventually he/she may need sick days and even treatment.

With CoWelder

Your dedicated welder is comfortably watching the CoWelder carrying out the back-busting runs, while he/she prepares the next workpiece.

"It is hard to motivate an employee to do the same work for 700 hours. That is not a problem with the CoWelder."

- Roland Kuhz, Owner of Kuhz Metallbau, Germany

The welder avoids welding fumes

Electric arc welding generates welding fumes and UV radiation. Inhalation of welding fumes can cause short-term discomfort but in the long term, exposure may be harmful to the welder. That is why use of ventilation and respiratory protective equipment is indispensable. However, to simply not be near the weld pool will always be the best way to eliminate the risk of inhaling welding fumes.

Luckily, the CoWelder doesn't mind.

Without CoWelder

When your welder is bent over the arc for hours every day, there is a risk that exposure to harmful welding fumes and UV radiation may cause health problems in the long run.

With CoWelder

The CoWelder doesn't mind welding fumes and radiation. It will keep on welding non-stop, without pausing to breathe. Your welder can stand a safe distance and avoid exposure.

"The CoWelder can produce roughly the same quantity as two skilled welders. In that way, it relieves the welders from the physically hard work of manually welding small components for a long time."

- Anders Marcher, in charge of CoWelder at Ole Almeborg A/S, Denmark

Ready to talk more about CoWelder?

Our CoWelder experts are ready to help you improve your working environment and rationalise your welding production. Drop us a line, and we will have an informal chat about your possibilities.