Svend Frederiksen Maskinfabrik

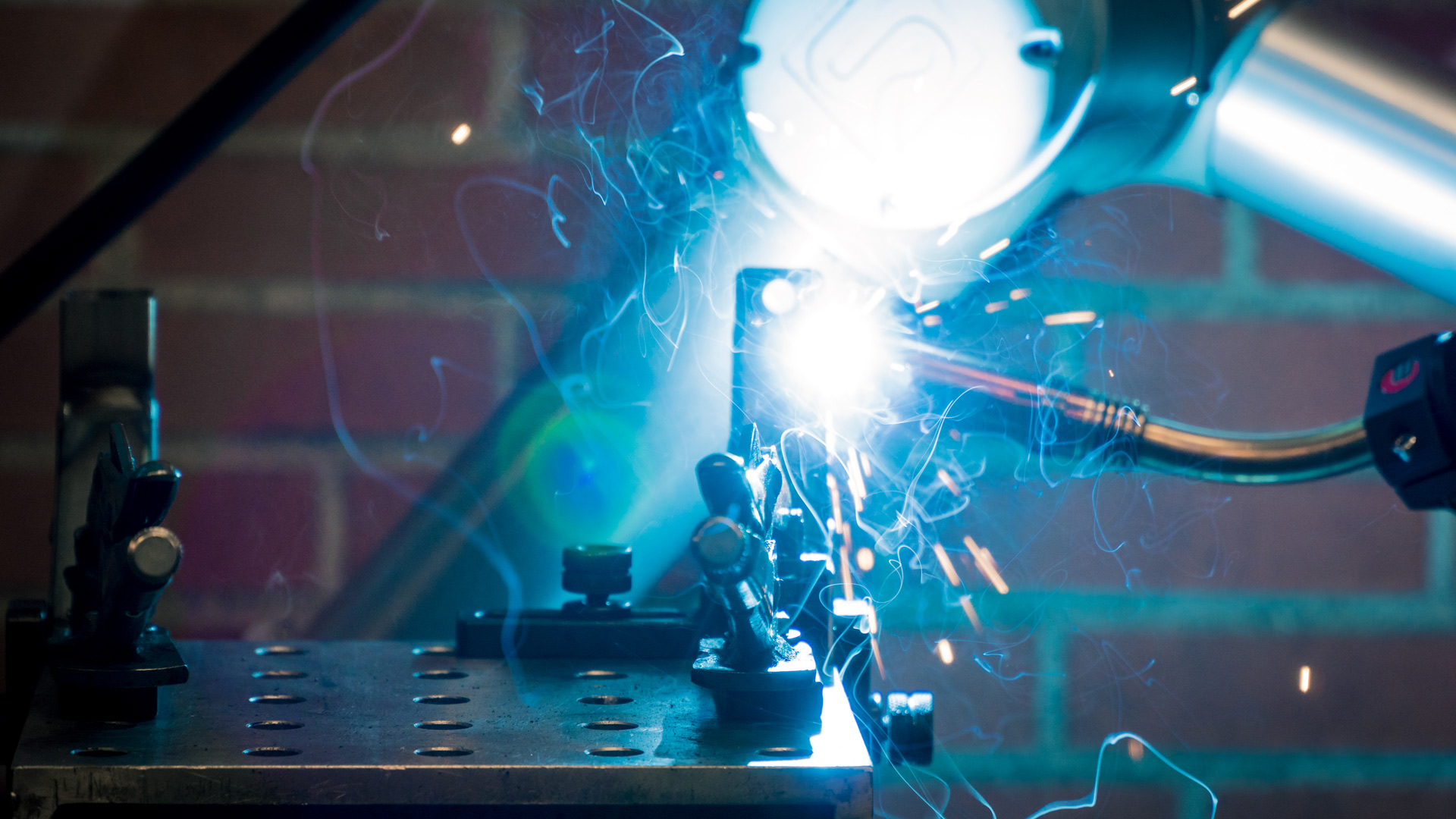

With a view to optimising its complex manufacturing process, Danish subcontractor Svend Frederiksen Maskinfabrik recently invested in a Migatronic CoWelder™, a collaborative welding robot.

Producing customised units requires flexibility

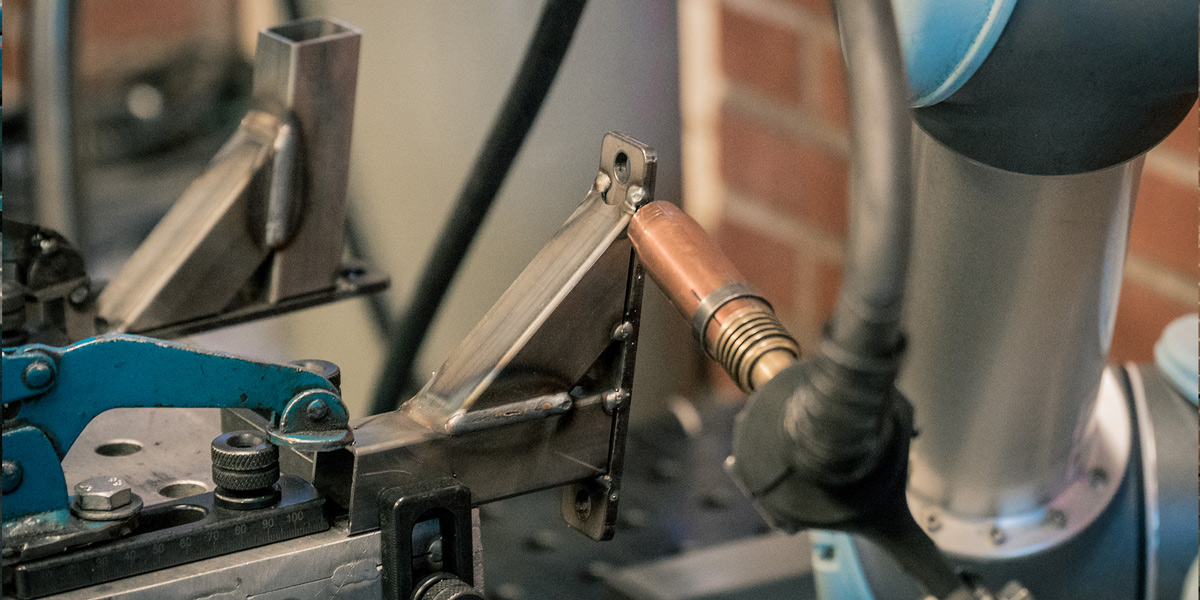

As a subcontractor, Svend Frederiksen Maskinfabrik specialises in the production of custom-made welded steel constructions, profiles, machine parts, fittings and components for large and medium-sized companies requiring external steel processing. The company offers customised units in both small and large batches, which places high demands on the skill and flexibility of its workforce and manufacturing facilities on the island of Funen.

"Our typical batches vary from a single customised unit to 1000 units, which emphasises the importance of maintaining an agile manufacturing process that can be adapted easily to the specific needs of our customers", Fleming Frederiksen, CEO of Svend Frederiksen Maskinfabrik, says.

"Our business is completely dependent on the qualifications and craftsmanship of our workforce, and we have always prioritised to provide them with equipment of the highest quality and with cutting-edge technology. Welding machines are no exception to this principle, which is why Migatronic has been our preferred supplier of welding equipment for more than 30 years", Fleming Frederiksen explains.

Challenges the manufacturing method

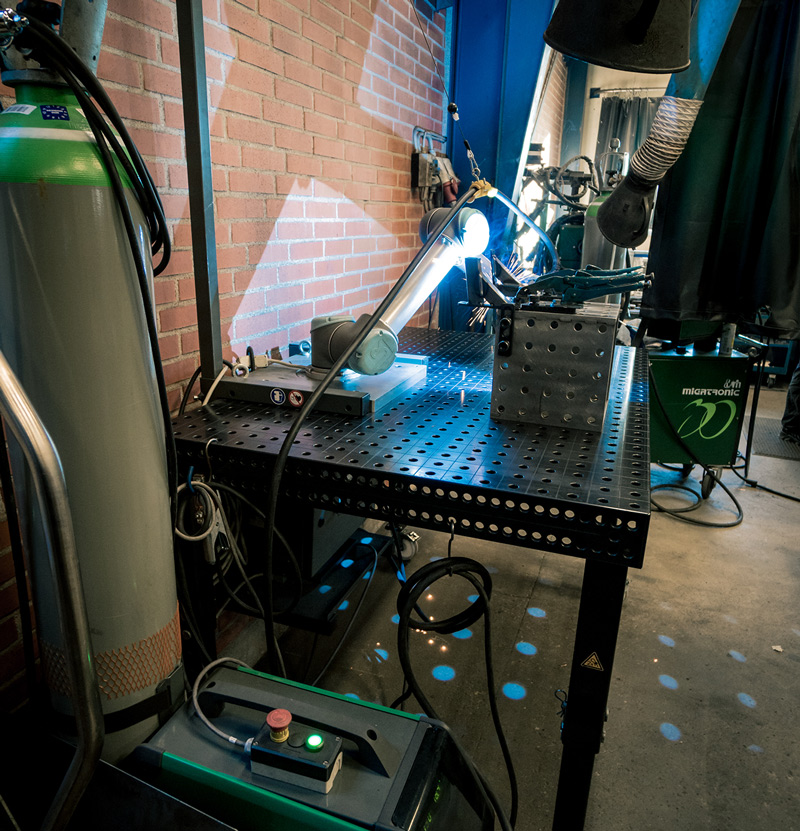

With a view to optimising its complex and alternating manufacturing process, Svend Frederiksen Maskinfabrik was recently introduced to the Migatronic CoWelderTM; a small automated welding solution, which – as the name indicates – works alongside its human colleagues without the need for a safety guard, due to its CE-certification.

"We are very pleased with the flexibility and user-friendliness of the CoWelder, as it fits perfectly with our need for an automated solution that can accommodate a great variation in design and batches. The fact that our apprentices are the most frequent users of the CoWelder, just emphasises how easy it is to handle", Fleming Frederiksen says.

Conclusion

"By investing in the CoWelder, we have challenged a key area of our own manufacturing method, as this is our company’s first automated welding solution. We are still in the process of learning how to put all its features to optimum use in our manufacturing process, but we are very pleased to count the CoWelder as a member of our team", says Fleming Frederiksen.