AIZ gGmbH

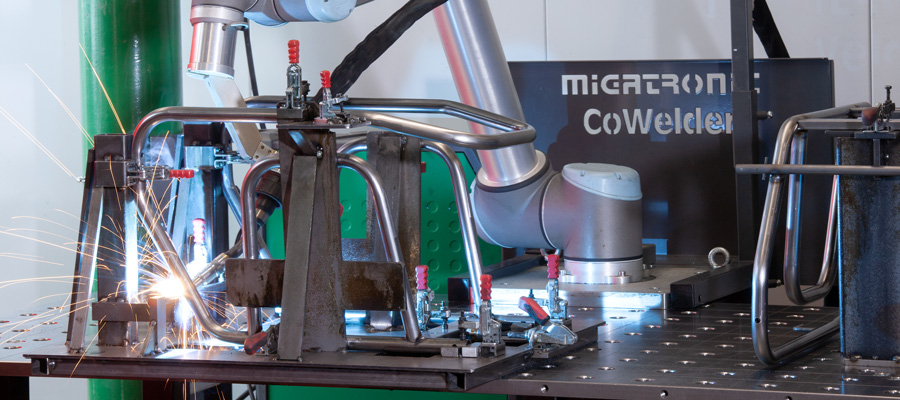

AIZ gGmbH is a non-profit industrial company in Germany that employs and trains people with physical and mental disabilities. To support the increasing number of disabled welders in its production line, AIZ has invested in three CoWelder welding robots from Danish welding machine manufacturer Migatronic; one for TIG welding and two for MIG/MAG welding.

AIZ is a manufacturing and service company based in Lautlingen in southern Germany. Aside from providing products and services to other businesses, the company also supplies products to end-users under its own consumer brand, Albkult. Founded in 2007, AIZ is part of the Lebenshilfe Zollernalb Group, which also includes the two non-profit companies ZAW and ISBA. The purpose of the group is vocational training and occupational integration of people with physical and mental disabilities.

Today, AIZ employs 60 people out of which 40 % has a physical or mental disability. So far, the company’s disabled employees have not been able to contribute to AIZ’s welding production, which is why the company started looking for innovative welding solutions:

- We manufacture metal components for a broad range of industries – from medico and furniture to the German automotive industry. The other part of our company concerns our own brand Albkult, which mainly comprises canopies and outdoor furniture in steel and wood for the B2C market, Daniel Gonser, Operations Manager at AIZ, says.

- The majority of our products are made from steel or consist of steel components, which makes welding essential in our production process. That is why we have looked for new technologies to support our disabled employees. This enables us to train them in the craft of welding so that over time they will be able to contribute to our welding production.

New Opportunities for Disabled Welders

In the search for welding solutions that could modernise the production line and empower the company’s disabled employees, AIZ was introduced to the CoWelder from Migatronic, which, according to Daniel Gonser, is the leading collaborative welding robot on the market:

- The CoWelder does not necessarily require any additional parts and comes as a complete plugin welding robot, ready to use shortly after installation. On top of that, the efficiency and welding quality of our new robot colleague is spectacular, and it always delivers in terms of precision, finish and uniformity, he says.

Impressed by the collaborative welding robot’s qualities, AIZ invested in its first CoWelder with TIG welding technology a year ago. Recently, the company added another two CoWelder MIG/MAG with synergic welding programs, pulse function, IAC (Intelligent Arc Control) and IGC (Intelligent Gas Control). The CoWelder with TIG is mostly used to manufacture AIZ’s own brand. The two collaborative robots for MIG/MAG welding are mainly used for large batch production of metal parts for other businesses. According to Daniel Gonser, the three CoWelders are all an integral part of the production line, and the company’s investment has led to new possibilities for AIZ’s disabled welders:

- From our company’s perspective, the CoWelders’ biggest advantage is that our disabled colleagues can operate the robots by themselves. The fact that we can now teach all our workers how to weld, has opened the door to a future job in the welding industry for many of our colleagues with disabilities. This is also why they have welcomed their new robot colleagues with open arms, and they can all be very proud of their ability to operate a highly advanced welding robot like the CoWelder.

Automation for a Better Future

According to Jürgen Ganzenmüller, Branch and Sales Manager at Migatronic Germany, the CoWelder is ideal for industrial companies like AIZ:

- The CoWelder is very easy to operate and adjust according to the design of any given component. This makes it the ideal solution for a non-profit company like AIZ, he says and continues:

- The CoWelder is an immensely durable and efficient solution suited for small and large batch component production due to its high level of usability. Because of its spectacular qualities, which can lead to significant optimisations in any company’s production line, the CoWelder is relevant for just about every company in the welding industry.

Facts About the CoWelder

- Complete welding solution with a MIG/MAG or TIG power source

- Quick setup: Supplied fully assembled with a welding torch and a table mount

- Ideal for welding simple workpieces, no matter the quantity and frequency

- Easy and intuitive programming and reprogramming even for inexperienced operators

- A highly efficient and cost-effective automated solution for all types of production companies

- User-friendly, adaptable and flexible automated welding solution that can be moved around easily

- IGC® (Intelligent Gas Control) for optimal gas shielding and up to 50 % gas savings

- Part of the team: Operates side-by-side with its human colleagues with no need for safety guards since the solution is CE certified (also certified with the Norwegian HMS-certification)