FM Bulk Handling - Fjordvejs

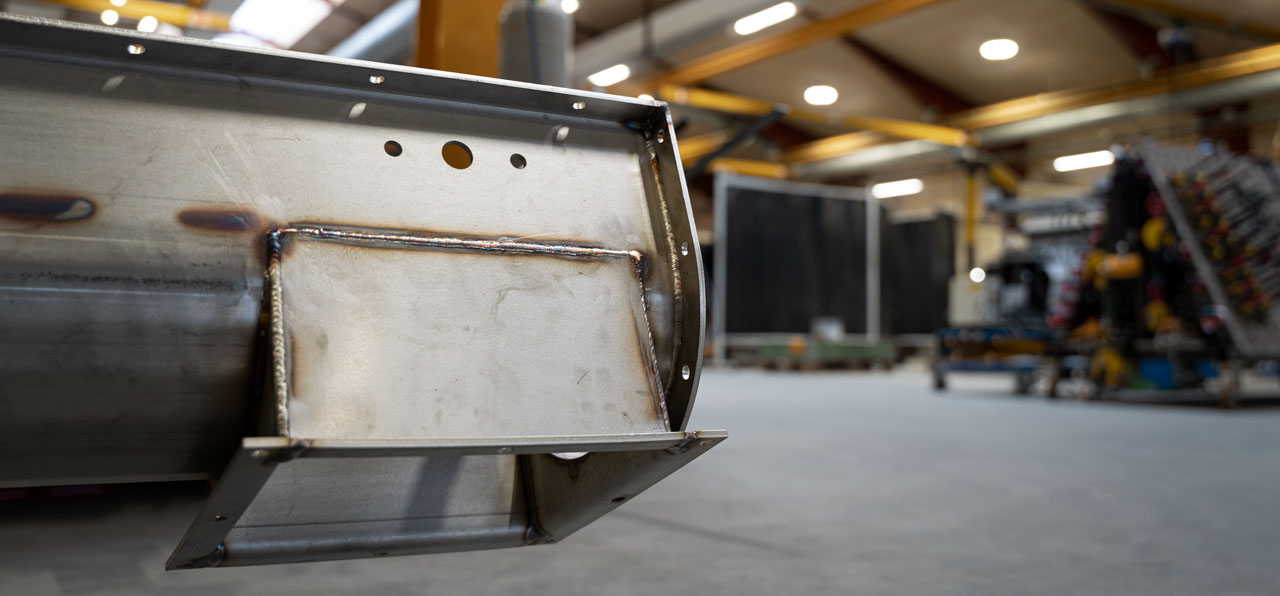

FM Bulk Handling - Fjordvejs welds many meters every day. PowerArc Pulse technology significantly increased their welding speed and reduced the time spent on large components. This productivity improvement has enhanced FM Bulk Handling - Fjordvejs's competitiveness and their ability to pursue a greater number of stainless steel orders through successful bidding.

|

Industry

|

Workforce

|

|

Products |

Welding machines |

The challenge

An increasing demand for stainless steel solutions made FM Bulk Handling – Fjordvejs look for solutions to optimize their welding processes to increase productivity. At the same time, it is important for them to keep up with developments in welding technology to remain competitive.

The solution

FM Bulk Handling – Fjordvejs welds a great many meters every day, so it was an easy choice to speed up welding. The PowerArc Pulse welding technology does exactly that: increases the speed of pulse welding and treats stainless steel more gently.

The outcome

PowerArc pulse has increased the welding speed by 25% and with the gentle process, welders spend less time on post-treatment. At the same time, the company can bid on more stainless steel orders than before.

Increased welding speed

The 20 welders at FM Bulk Handling - Fjordvejs typically must make multiple welds to produce most of the large stainless steel components. With PowerArc Pulse as an extension of regular pulse, it is possible to speed up the process and weld longer joints in shorter time without compromising the weld quality - and without spatter.

"PowerArc Pulse has increased our welding speed for pulse by up to 25 percent – mind you, without compromising on quality and fusion. It is great for welding over long distances, and we use it for many different welding positions, e.g., top-down/side-in and vertical-down welding positions. It also handles fillet welds with throat thickness down to 3 mm without burning through the material”.

|

|

Jannick Knudsen Shop Foreman Assistant |

Substantially less need for post-treatment

The production of large components for solutions such as screw conveyors and silo bucket elevators requires a significant amount of time dedicated to welding. With many welds on the same stainless steel component, there is a high risk of stressing the material during the intense heat treatment that welding is.

PowerArc Pulse adjusts the arc which makes the welding more concentrated and stable. This provides a lower heat input and less spatter. Using this gentler process, welders spend much less time on post-treatment.

"PowerArc Pulse has reduced the number of deformation and stresses in our finished welded components, and the amount of weld spatter has also been reduced. In total, it has significantly reduced the time we spend on post-treatment and stress relieving."

|

|

Jens Kristian Christensen Production Manager |

Increased production capacity

With many welding hours, there is a large potential for improvement with PowerArc Pulse. The more you weld, the more you can improve. FM Bulk Handling - Fjordvejs has succeeded in utilizing the technology to such an extent that the investment in PowerArc Pulse for their 12 Sigma Select welding machines pays for itself.

"We sometimes experience increasing demand for stainless steel products, so the time had come to optimize our machines to be able to better solve this kind of task. PowerArc Pulse has made it possible for us to bid on more stainless steel orders than before. In addition, the technology reduces the amount of filler material, so from a financial point of view, the investment has paid for itself in a short time."

|

|

Jeppe Bergmann Rasmussen Owner |

Fast implementation

It may take some time to get used to using the fast pace of PowerArc Pulse technology. But with the help of one of Migatronic's welding specialists, FM Bulk Handling - Fjordvejs' welders have been quick to adopt the new technology:

"Migatronic has been involved in the implementation. They trained our welders in how to best use PowerArc Pulse and adjust the machine correctly. They often come to visit, where they continuously advise us about welding."

|

|

Jens Kristian Christensen Production Manager |

Inspired?

Do you want some of the same results as FM Bulk Handling - Fjordvejs? Then check out PowerArc Pulse or Sigma Select.